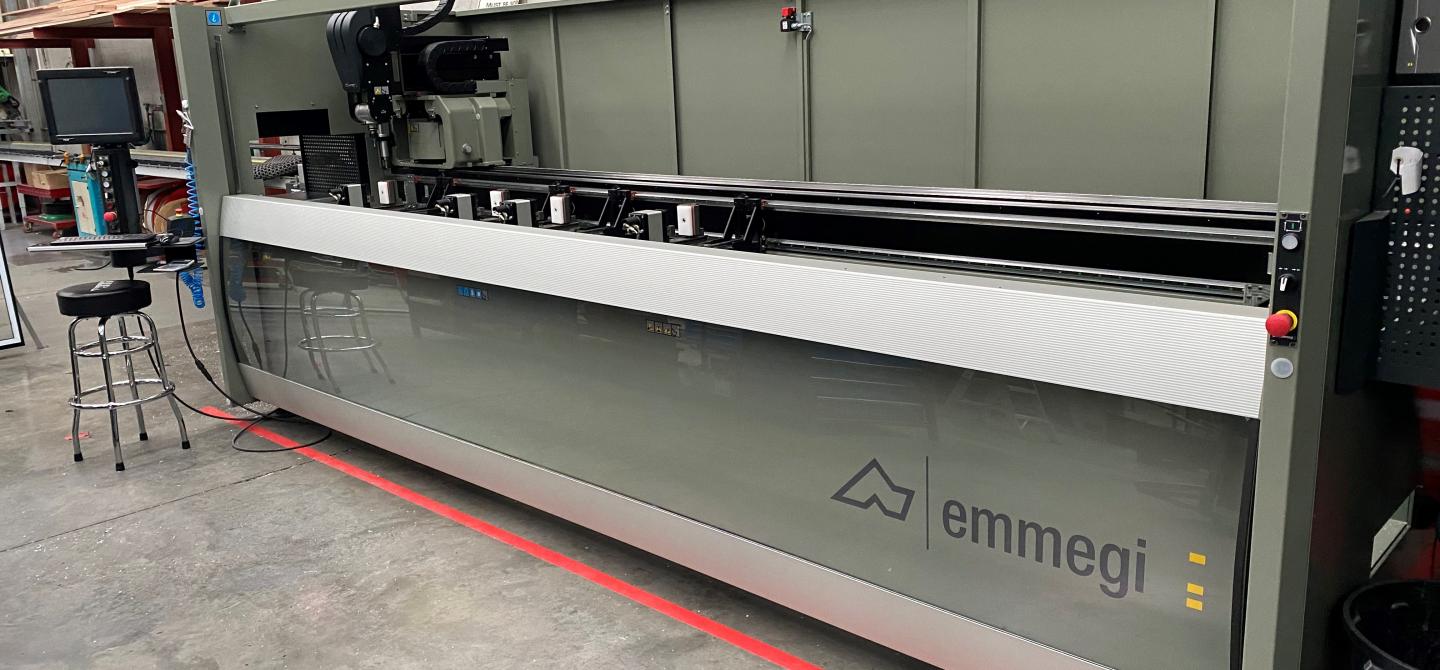

Thermeco Doubles Their Capacity

28th July 2020

Introducing our brand new CNC Machine by Emmegi sourced from Alumach. This machine is a huge asset to Thermeco and the team providing a limitless amount of efficiency and precision.

Due to the increasing demand of projects, it was time to level up our tool kit with this master machine. The time and care it would usually take to prep and machine profiles is now made much easier and exceptionally quicker saving a lot of time and enabling the ability to turnover profiles at a rapid pace with no room for error - allowing us to push through double the amount of work.

The machine is automatic, so the user can be working on other tasks while it's machining and moves along the X and Y axis super fast. It's so smart that it can machine any shape required including any custom shapes/slots/holes. All programming is designed and entered on any computer with the software where jobs can be input into the machine. Then, with the press of a button, all bars and profiles are perfectly prepped ready for fabrication.

The machine is extremely user friendly and very safe. There are multiple safety components to avoid any accidents making injury or damaging material almost impossible.

Machining centre CNC with 4 controlled axes, used for the working of bars or aluminium, PVC, light alloys in general and steel pieces up to 2mm. Automatically positioned clamp unit. It has a 4 or an 8 place (optional) tools storage, with the possibility of hosting 2 angular units and one milling disc, to perform machining on the 5 sides of the piece. Machines bars up to 4m in length. The 4th CN axis allows the electro spindle to continuously rotate to from 0° to 180° to perform the work on the profile edge. It also has a mobile work surface that facilitates the piece loading/ unloading operation and significantly increases the workable section.

https://www.emmegi.com/en/product/machining-centres/phantomatic-x4